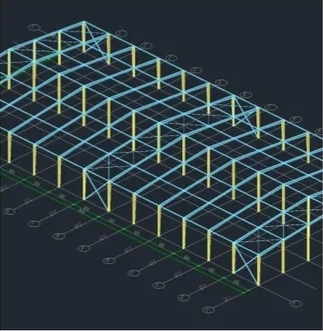

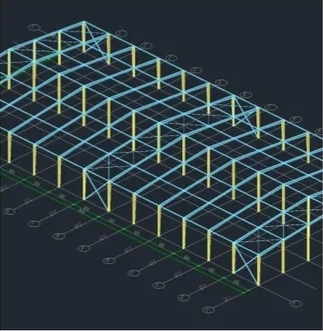

Light Metal Industrial Steel Building Large Span Free Design

Drawing

China Premier Steel Structure Building Manufacture for the Global Market

With a solid foundation in the Chinese domestic market, we are now

expanding our reach to bring our high-quality steel structure

factory buildings to the world.

Our products are a combination of traditional Chinese craftsmanship

and modern technological innovation, designed to meet the diverse

needs of international customers.

Product Description

Prefabricated steel structure building has features of high fire

resistance, strong corrosion resistance.

Its main bearing component is composed of steel material, like

steel column, steel beam, tie beam, steel roof truss, bracing bar

and wall roof purlin etc.

Each component uses welds, bolts or rivets to connect.

Prefabricated steel components will be well fabricated in the

workshop so that they could be installed directly on site. Then the

intallation will much easy and quick to process.

| Product Features | |

| - Structural Stability | Utilizing high-strength steel materials meticulously crafted.

Through professional design and precise processing, it can

withstand natural disasters such as earthquakes and strong winds of

a certain intensity. Designed in accordance with international

building standards to ensure structural safety and reliability. |

| - Spatial Flexibility | Can be customized in terms of different spans, heights, and lengths

according to the building regulations and actual requirements of

the customer's location. The internal space is designed flexibly to

facilitate the customer's layout according to their own production

or usage needs. |

| - Energy Conservation and Environmental Protection | Selecting high-quality thermal insulation materials to reduce

energy consumption and meet international environmental protection

requirements. |

| - Anti-Corrosion and Durability | After professional anti-corrosion treatment processes, prolonging

the service life of the steel structure and reducing the

maintenance cost in the later period. |

| -Wide Application | Steel Structure can be applied to factories, warehouses, office

buildings, gymnasiums, hangars and so on. It is not only suitable for single-story long-span buildings, but

also can be used to build multi-story or high-rise buildings. |

| Product Specifications | |

| - Size Range | Length: customizable;

Width: customizable;

Height: customizable. |

| - Steel Material | Commonly used high-quality carbon structural steels in line with

international standards such as Q235B and Q355B |

| - Roof and Wall Materials | The roof is made of high-quality color steel sandwich panels. The

core materials can be rock wool, glass wool, etc., with good

thermal insulation, heat preservation, and fireproof performance.

The walls can be made of color steel plates or other composite

panels to meet the building appearance and performance requirements

of different regions. |

| Design and Construction | |

| - Design Team | Having a professional international design team, familiar with

building codes and standards of various countries, and capable of

providing personalized design solutions according to the special

requirements of the customer's country and region. |

| - Construction Team | Having a professional team with rich experience in overseas project

construction. They strictly follow international construction norms

and standards to operate, ensuring the project quality and

progress. |

| Quality Assurance | |

| - Material Quality Assurance | All materials comply with national standards and industry

specifications, providing material quality inspection reports. |

| - Construction Quality Assurance | Strictly implementing the quality inspection system, with each

process undergoing strict quality testing to ensure the project

quality meets the requirements. |

| Price and Customization | |

| - Price Range | According to different specifications, configurations, and

customization requirements, the price varies. Providing detailed

price calculation methods and quotation lists. |

| - Customization Service | Can be customized according to the special needs of the customer in

terms of special functional zoning design, appearance modeling

design, and equipment installation support, etc. |

Our Advantages

1. Customized Design

We are a professional factory with remarkable achievements in steel

structure design and manufacturing. Our professional design team,

armed with extensive industry experience, proficiently uses various

advanced software to meet the diverse needs throughout the project

lifecycle.

(1)Initial Planning Stage: We capture every idea of our clients with

3ds Max. By creating realistic renderings and animations, we

showcase the project vision, facilitating clients' quick decision -

making and helping them define the design direction.

(2)Technical Design Stage: SAP2000 software enables us to simulate

various complex steel structures. Through repeated design

optimizations, we ensure structural safety while achieving rational

material utilization and reducing project costs.

(3)Design Deepening Stage: STAAD.Pro serves as an assistant for our

structural analysis and optimization. Using this software, we build

precise mechanical models to evaluate key performance indicators

such as the stability and load - bearing capacity of steel

structures.

|  |

| 3D Model | Calculation Model | Detailed Model |

|  |  |

2. Advantages of Steel Structure

1. Rapid Construction: When compared to traditional concrete structures, steel - framed

prefabricated buildings offer a much faster construction process.

The modular manufacturing approach allows for concurrent production

and site preparation. . 2. Optimized Capital Deployment: The shorter construction cycle of steel - structured building

alleviates the burden of long - term capital occupation. This

reduces the risk associated with market uncertainties. 3. Substantial Foundation Cost Savings: Steel structures are lightweight, imposing less load on the

foundation. As a result, simpler and less costly foundation designs

are sufficient. This not only cuts down foundation construction

expenses but also reduces the overall project budget. |  |

3. Product Packing

|

To safeguard all steel structure building components during

transportation, we opt for high - quality packaging solutions. The primary steel frames are covered with a thick plastic wrap and

tightly strapped with strong steel bands, effectively protecting

them from impacts and scratches. Wall and roof panels are bundled up, and their stability is

enhanced by securing them with steel straps or high - strength

ropes. As for small components such as bolts, nuts, and screws, they are

carefully packed in individual boxes, clearly labeled with their

specifications for hassle - free identification.

|

Wide Range of Applications

Our Steel Structure Workshop Warehouse is perfect for various applications, including manufacturing

plants, automotive repair shops, and woodworking workshops, among

others. The versatility and durability of our steel structure

workshop Warehouse make it ideal for various industries and businesses.

In summary, our Steel Structure Workshop Warehouse is a reliable and customized solution for your building facilities

and construction materials needs. With our galvanized steel

structure, custom steel fabrication capabilities, and various door

and roof cladding options, we can create a workshop warehouse that meets your unique requirements and preferences.

We take pride in our custom steel fabrication capabilities, which

means that we can create a Steel Structure Warehouse Workshop that suits your business requirements. Whether you need a

large workshop for industrial purposes or a smaller one for

personal use, we can design and build it for you.

Support and Services

Our Steel Structure Workshop Warehouse product comes with

comprehensive technical support and services to ensure a smooth and

successful installation process.

Our team of experts is available to provide guidance and assistance

at every stage of the project, from design to construction. We

offer detailed product specifications, CAD drawings, and

engineering calculations to help you make informed decisions and

ensure compliance with industry standards.

In addition, we provide on-site installation supervision and

training to ensure that the installation is carried out to the

highest standards of safety and quality. Our goal is to ensure that

you have a reliable and durable workshop that meets your specific

needs and requirements.

| service | Quality inspection | Factory Self-inspection by QC Customer inspection Third party inspection |

| Design and Drawing | Construction blueprint design Steel structure detailed drawing 3D model by auto cad / ifc Install detailed drawing |

| Manufacture | Manufacture various steel components based on different conditions

of projects, steel plates, sectional profiles, metal sheets,

flashing, ventialtor and other building accessories to guarantee

the whole construction project |

| Installation | Install detailed drawings to guide On-line / remote guidance for installation. Engineer to guide on site or The installing team to process all

installation on site. |

LJ Group Projects

Order Procedure

A. If you have the drawing of your project:

We could check your drawing details and quoted accordingly. After

all details are confirmed. The rest full service of production,

shipment and installation guide will be offered.

B. No drawing:

Our designer team will make drawings for your check with free

technical support. Firstly we need to confirm your project details

as belows. If you help to confirm in advance, we could process for

you quickly and directly.

1. Dimension:Length × width × height .

2. Doors and Windows: Dimension, quantity, position.

3. Local wind load, snow load, roof load...

4. Roof and wall materials:Insulated Sandwich panel or metal sheet,

birck wall's height

5. Crane and tons?

6. Building usage could also help us to choose the right materials

and plans for you.

7. Other requirements:such as anti-corrosion requirements, parapet,

messanine, partitions, decorative materials or others